Iridium have just launched their latest satellite transceiver, the Iridium Certus 9704. In this post we’re going to explore how this module compares with other satellite IoT modems, the Iridium 9603 and Certus 9770. We’ll look at ideal use cases for the new transceiver, how to get the best out of the device, and how to get started.

What is the Iridium Certus 9704?

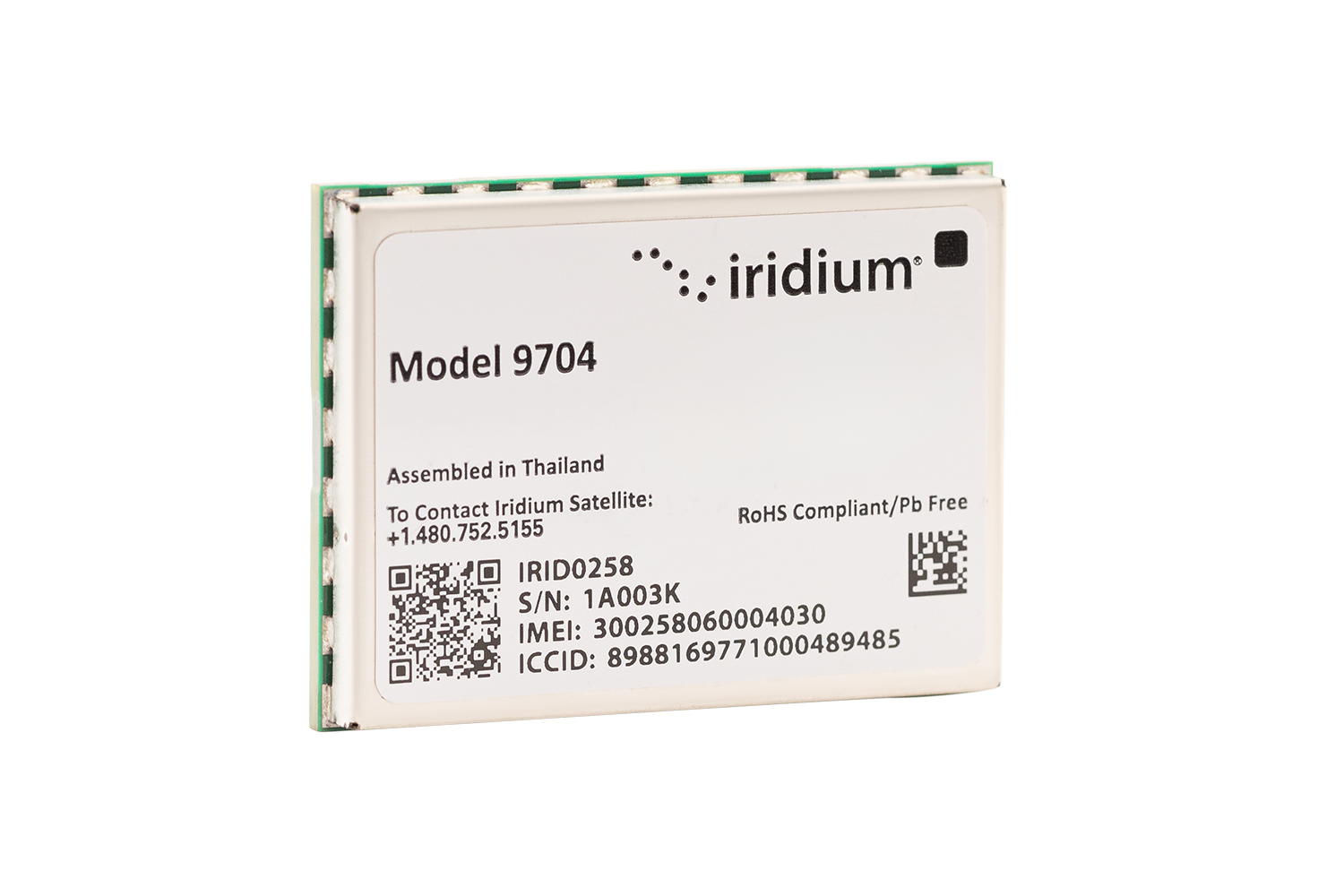

The 9704 is a small, lightweight and low power satellite IoT transceiver that connects to the globally available Iridium satellite constellation.

It leverages Iridium Messaging Transport (IMT), a message-based service which allows users to transmit data packets of up to 100 kB. What is IMT?

What Applications are Suited to the 9704?

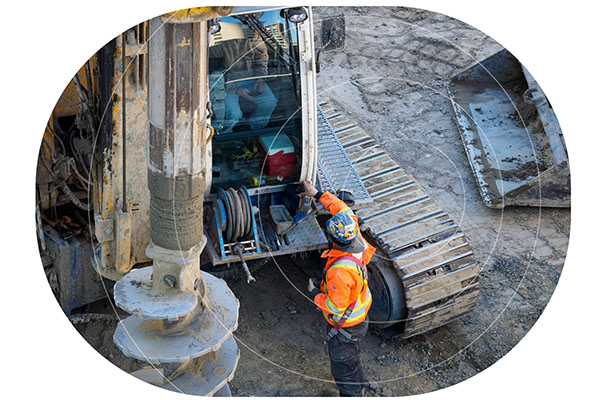

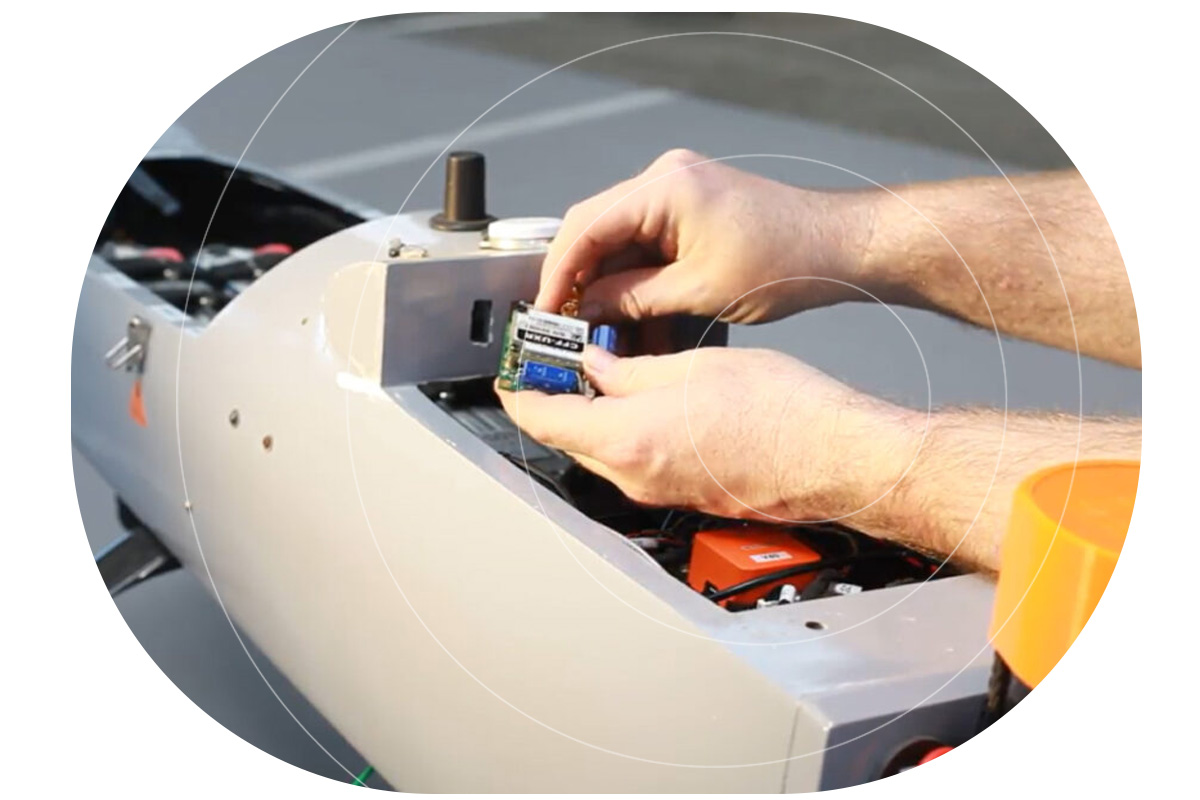

The 9704 has been designed to consume very little power, so it’s ideal for remote, battery-powered applications. For example, telemetry from heavy machinery; SCADA readings from unmanned substations or infrastructure; aggregated gateway / hub data; data logger transmissions.

It can also be used for simple UxV commands; stop, start, return etc.

How Does the 9704 Differ from the 9603 Transceiver?

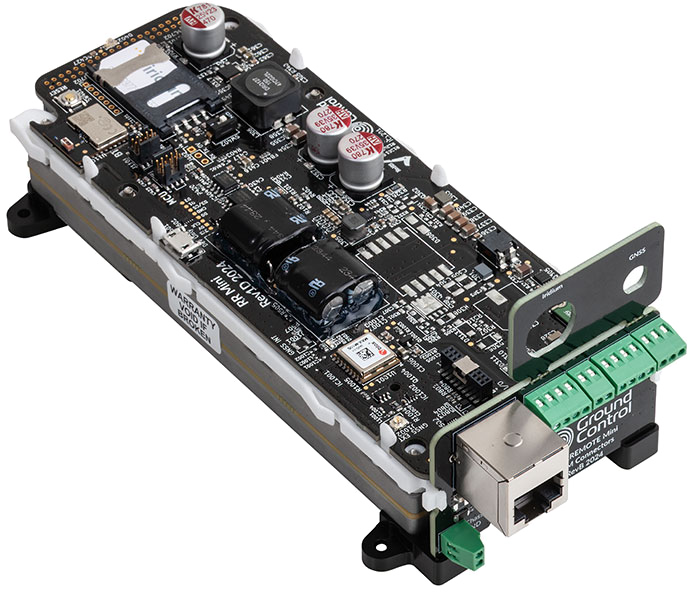

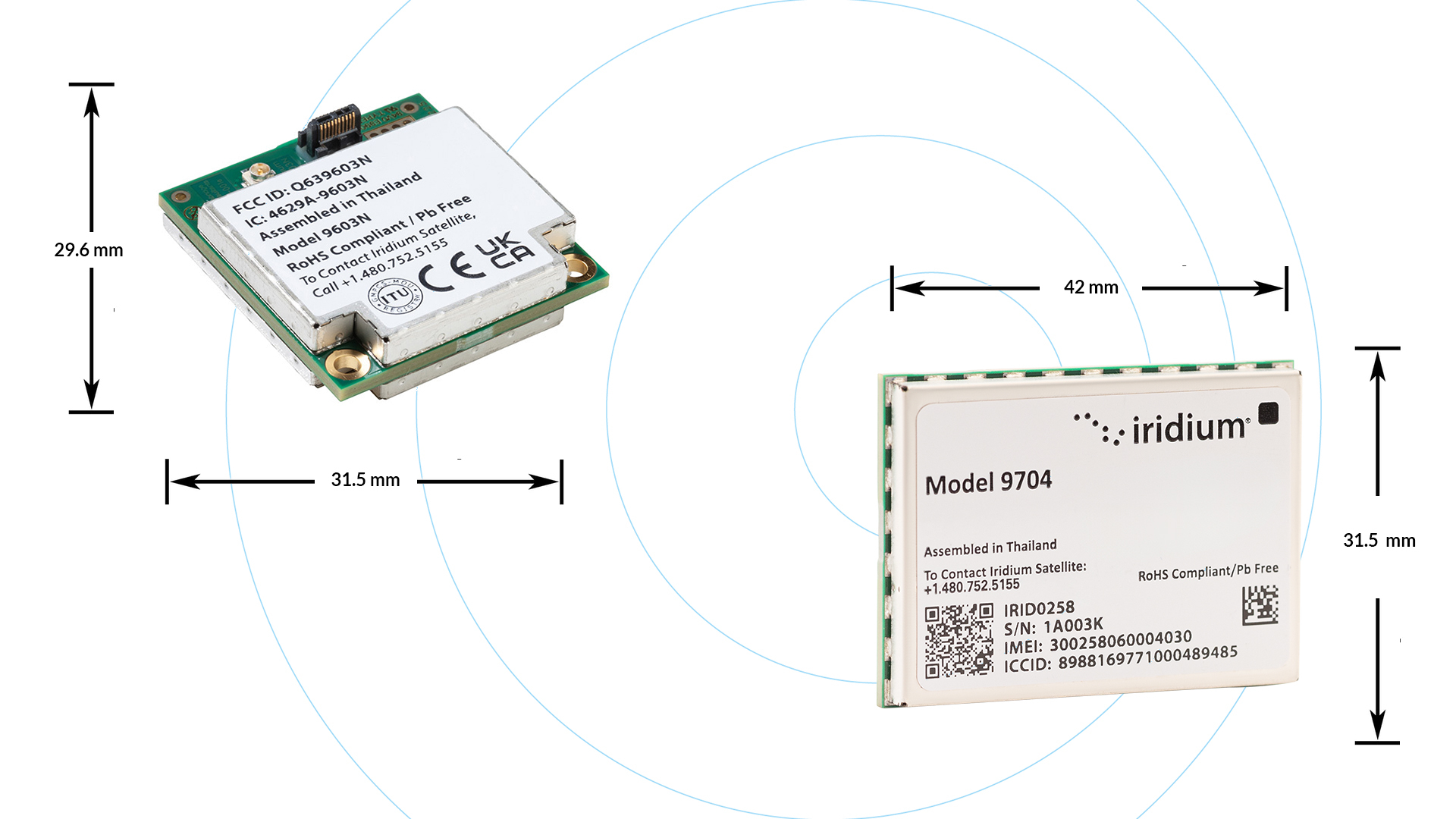

The 9704 module is 34% smaller than the 9603N modem: 31.5 x 42 x 3.8 mm vs. 31.5 x 29.6 x 8.1 mm, and 12 g vs. 11.4 g respectively*.

The 9704 also boasts an 83% reduction in idle power consumption compared to the 9603. The message size for the 9603 is considerably smaller compared to the 9704; 340 / 270 bytes (Short Burst Data) vs. 100 kB (Iridium Messaging Transport). The link speed is also doubled with the 9704; from 2.4 Kbps to 4.8 Kbps.

Applications best suited to the 9603 include asset tracking, environmental monitoring and fleet management; it remains the most cost-effective way to move very small volumes of data using the Iridium satellite constellation. But for many applications, IMT will be a more cost-effective means of transmitting IoT data.

How Does the 9704 Differ From the 9770 Transceiver?

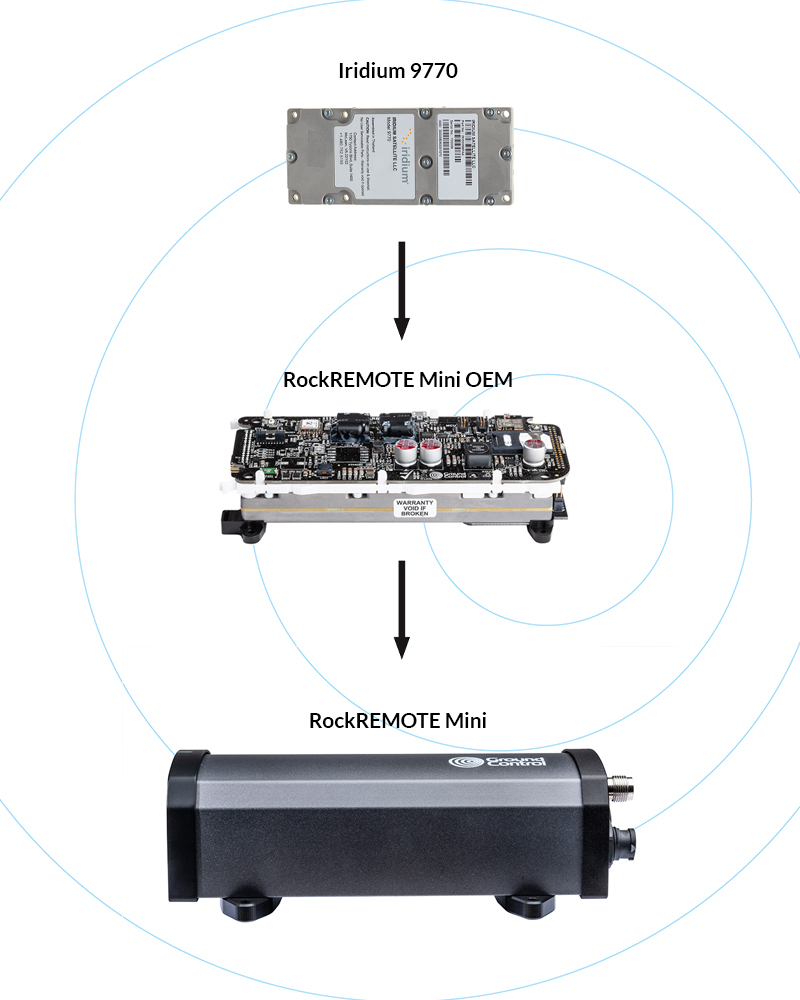

The Iridium Certus 9770 modem is a more powerful device. It can send data over IMT, but also over IP, creating greater flexibility and making it more suitable for applications where real-time command and control is required – for example, piloting a drone BVLOS.

The 9770 sends data far more quickly; 22 / 88 Kbps vs the 9704’s 4.8 Kbps (Tx/Rx). But this comes with a greater power draw; the 9770 requires 3.5 W to transmit/receive, whereas the 9704 requires roughly 0.9 W.

The 9770 is also larger and heavier than the 9704; 140 x 60 x 16 mm and 185 g vs. 31.5 x 42 x 3.8 mm and 12 g respectively.

The Certus 9770 can be used for voice communication, and the 9704 is data only.

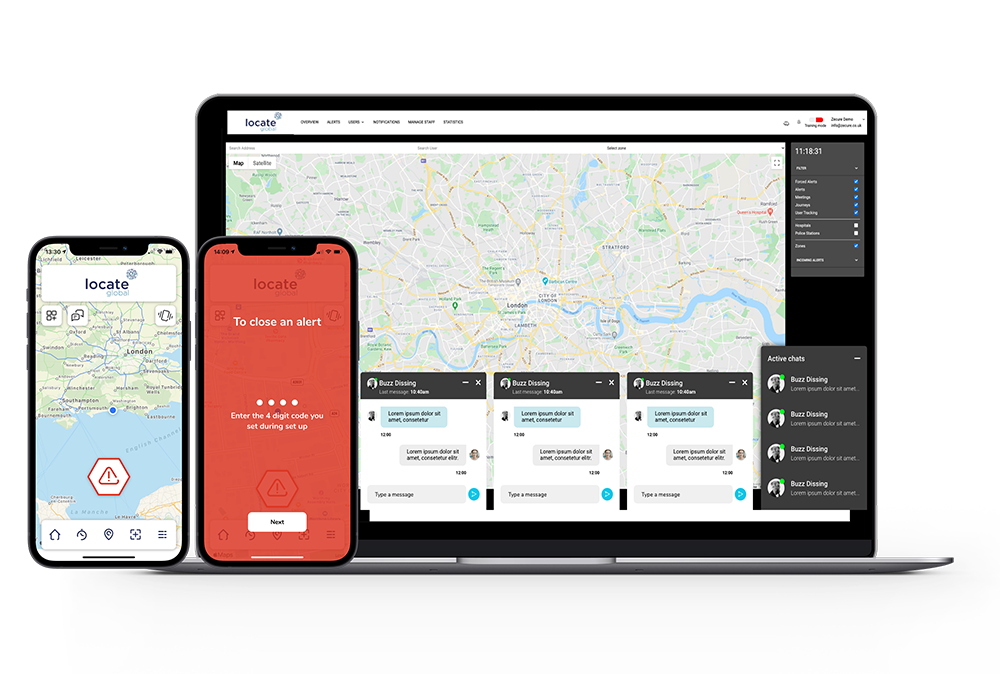

Devices utilizing the 9770 transceiver are ideal for remote control of assets such as UAVs and USVs; or when it’s important that data is moved quickly, so any form of alerting mechanism such as remote security or systems failure alarms. They will also be the preferred choice of systems integrators who want the flexibility to switch between IP and message-based transmissions depending on the type of data being moved.

Which Devices Utilize the 9704 Transceiver?

At the time of writing, you can purchase an Iridium 9704 Developer Kit, which is a great way to evaluate Iridium Messaging Transport (IMT) in the lab and explore what the technology can do. We are IMT and Iridium experts, having worked with the Iridium development team for decades, and we are here to help you get the best out of Iridium Messaging Transport, whether you start with the Iridium kit or our own hardware.

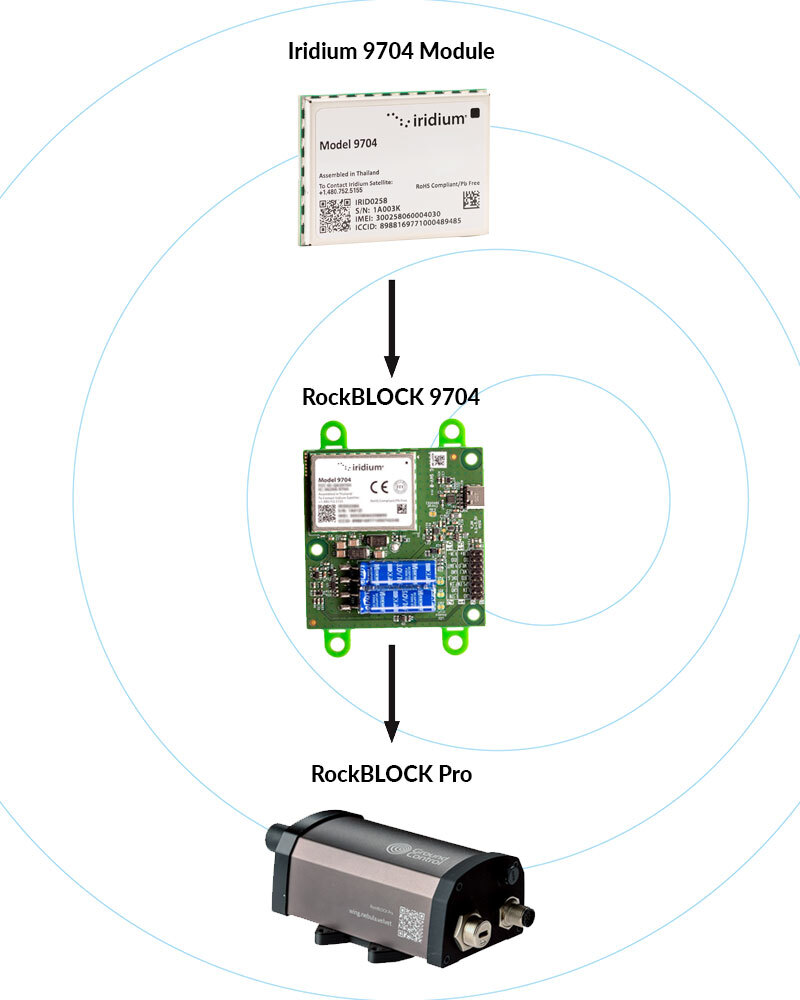

For projects that are likely to move beyond proof of concept into field deployment, we generally recommend looking at our RockBLOCK range as early as possible. RockBLOCK 9704 is designed specifically for integration into IoT products, with a production ready form factor, a lower unit cost than the Iridium developer kit, and a straightforward path from prototype to volume deployment. We’ve also built C, Python and Arduino libraries around the 9704 transceiver, so you can focus on your application logic rather than on low level protocol implementation.

We offer several devices that leverage the new technology, among them RockBLOCK 9704, for IoT applications, and RockBLOCK Pro, which is our multi-purpose, all-weather tracking and IoT device. If you’re unsure which route is best for your project, we’re always happy to talk through the options and trade-offs.

What is Iridium Messaging Transport (IMT)?

Launched in late 2022, IMT is Iridium’s most recent satellite IoT service. It is message-based, which is the most cost-effective and power-economical way to communicate with satellite networks (vs. an IP connection which has a substantial overhead).

With a message-based service, you pay only for the data you choose to transmit, and only when it’s successfully transmitted. However, a drawback of message-based services is that the data has to be reformatted before it reaches your preferred destination; unlike IP-based communication, it isn’t a commonly utilized format.

We built Cloudloop Data to address this challenge. This delivers simplified store and forward IoT messaging between your devices and cloud-based services. Messages can be fanned to multiple endpoints, from cloud providers like Azure and AWS, to IoT dashboards including ThingsBoard and ThingSpeak. You also have the option to consume the decoded data in your own system, through delivery methods including email, MQTT and HTTP webhook.

How to Get Started With the Iridium Certus 9704

We encourage you to contact us to discuss your application; we are Iridium experts, and will provide you with impartial advice on the best airtime, service and hardware to best meet your needs.

We’re responsive, friendly and helpful, and we genuinely love helping people solve their remote connectivity problems, so please get in touch!

*Information on the 9704 is subject to change.

Get in Touch

To get in touch with our team of Iridium experts, please complete the form, email hello@groundcontrol.com, or call us on one of the below numbers.

We will respond to your message within one working day.