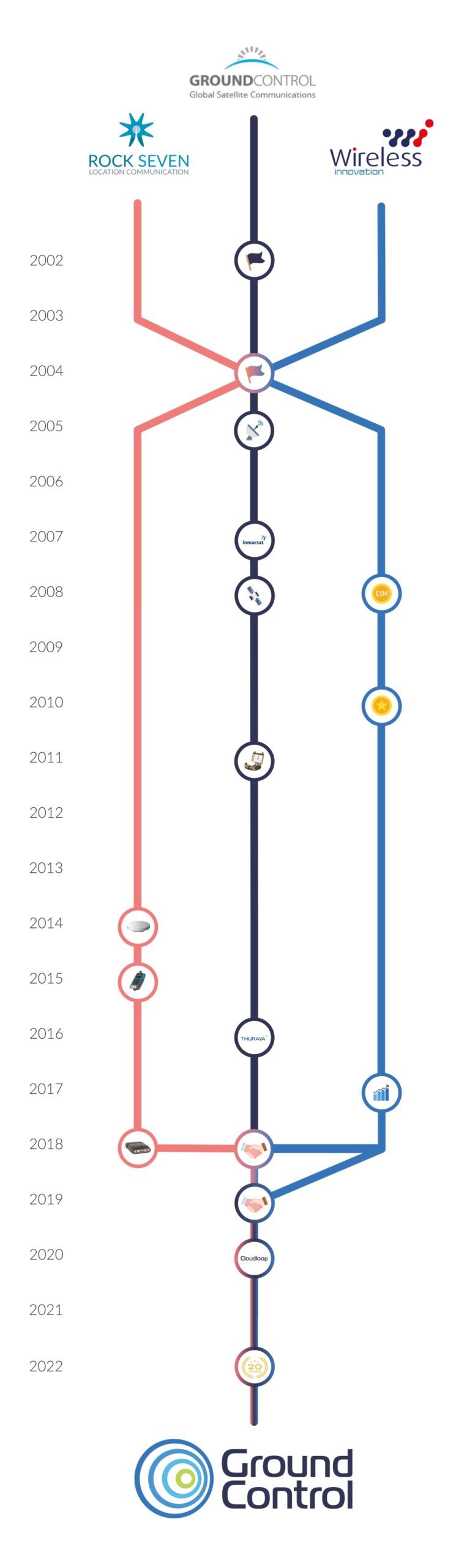

2022 marks the official 20th anniversary of Ground Control. Ground Control as we know it today, is formed from the merger of three companies – US-based Ground Control, and UK-based Wireless Innovation and Rock Seven. The result? A best-in-class IoT, M2M and critical communications service and technology provider, we service 4,500 customers across 120 countries worldwide.

We’re in a somewhat unique position at Ground Control, in that founding members from each business still consult and work within the company today. So to celebrate this impressive milestone, particularly in the fast-paced industry of satellite communications, we have amalgamated the “short” story of Ground Control.

Mark Wright, Founder of Ground Control in North America

Following the sale of his highly successful dial-up internet services business, ‘The Grid’, Mark went out on the open road with a newly purchased RV. In 1999, cellular data service didn’t yet exist and as Mark puts it – “as an internet guy, I wasn’t going to go without, so…”.

After some digging, Mark discovered Direcway satellite service for fixed home installations. It was wonderful new internet technology, but not a technology that could be taken on the road. Undeterred, Mark researched and found a company in Salt Lake City that manufactured RV TV antennas and commissioned them to develop a mobile solution for the Direcway dish in 2001. The result? DataStorm. The first affordable mobile satellite system in North America. The product was a huge success, meeting the needs of RVers and professionals across North America.

However, Mark felt that although the product was a great success, it was really lacking a quality service provider. So he founded Ground Control in 2002 to be that provider.

Mark’s background in internet services rapidly propelled Ground Control to become a leader in mobile satellite-driven internet services in North America. As Mark states – “the key to growth was always quality customer service, quality hardware and a bit of good marketing. Word of mouth is what really propelled Ground Control.”

Mark Wright, founder of Ground Control, his famous mobile VSAT solution, and MCD case-based system. Ground Control continues to design and build VSAT and portable satellite internet solutions from its base in California today.

Phil Rouse, Founder of Wireless Innovation in the UK

Around this time, in 2004, there were some exciting developments in the UK. Phil Rouse wanted to transform the business he worked for into one solely focused on satellite, radio and WiFi. Given his proposal was based on a Management Buy Out, he also had to pitch Wireless Innovation to potential employees he wished to move across. Phil states – “I was really humbled by their response. There is always an element of risk and these people had families to support, burgeoning careers. But they trusted me. And they were completely onboard for the vision I had for Wireless Innovation from the very beginning.”

Phil already had great relationships with TSAT, an expert SCADA device manufacturer, and Iridium, a satellite network provider specializing in global, low latency M2M connectivity. These enabled a strong sales proposition, and within just six weeks, Phil’s team had brokered a sale with large Italian utility company Telespatio. Even with the experienced team, given how new the company was, this was no small feat.

Phil Rouse, founder of Wireless Innovation and current Ground Control Consultant, the Wireless Innovation team outside the Churcham Business Park office and the TSAT.

Ric Searle, Co-Founder of Rock Seven in the UK

Meanwhile, also in 2004, Ric Searle and Nick Farrell started Rock Seven, developing solutions based on cellular location services which were emerging at the time. Early applications tracked the location of engineers for electricity companies, so they could deploy the nearest, appropriately skilled engineer to attend to faults in the network.

As time progressed, Ric explains – “I stumbled across an opportunity to deliver a tracking system for offshore yacht racing, which led to us finding an Iridium tracking product and developing a race management system and viewer, that became YB Tracking. We eventually decided that we could develop better hardware ourselves… So we did.”

This ultimately led to Rock Seven’s reputation for reliable, accurate global tracking of personnel and/or assets via relatively small devices. More commercial applications, including fisheries, emerged later on. Due to their early experience in offshore yacht racing, maritime is still a large focus for Ground Control today.

Ric Searle, co-founder of Rock Seven and current Chief Technology Officer at Ground Control. Enhanced RockSTAR device, very popular among lone workers today.

Since then, there have been multiple milestones for all three companies. To mention just a few, Jeff Staples (current President of North America) joined Ground Control in 2008 and in the same year, launched Ground Control’s flagship VSAT solution, the Toughsat XP. Through a program of continuous improvement, it remains a best-seller today. In 2008, Wireless Innovation landed their first £1 million deal and in 2010 were awarded the Queen’s Award for Enterprise. Not to be outdone, Rock Seven designed, engineered and manufactured the RockFLEET, an improved RockSTAR device and the RockAIR.

The new era: Private equity

2017 would mark the next significant moment in Ground Control’s journey. The founders of Wireless Innovation wanted to sell, Phil Rouse wanted to continue his journey with Wireless Innovation. So Phil set out to seek further financial investment, leading him to then Lyceum Capital, now Horizon – a UK-based private equity firm.

Horizon tasked Phil with creating a group of companies within the satellite and cellular space, which would enable each to expand their product lines and knowledge base and ultimately, bring new compelling solutions to the market.

Rock Seven, while serving a different customer base, had clear synergies through their use of Iridium’s short burst data (SBD) service, and their design and build capabilities made for a great fit. Similarly, the engineering capabilities of Ground Control, in addition to the US foothold, made the company a valuable addition to the newly formed group. The company benefited from the collective experience of its expert staff, supplier relationships, manufacturing capabilities, and a truly global customer base.

Phil explains – “I’ve always seen the key value-add of Wireless Innovation, now Ground Control, as a company capable and willing to take full ownership of the overall solution. There are a lot of players who offer plug-and-play communication systems, but ultimately Ground Control takes the time to understand how, what and why our customers applications work; the data required, frequency of communication needed and the utter importance of the customers application data. Ground Control uniquely positions itself to fully understand both ends of the data communications equation with our customers. And in my opinion, this understanding leads to better solutions for our customers and has been the differentiator between us and competitors.”

Celebrating 20 years of innovation

Shortly after the merger, Mark Wright retired and Phil Rouse stepped down in 2020, though both remain highly valued mentors for individuals and teams across the business. Alastair MacLeod was then appointed CEO of the Group and has made significant strides to amalgamate, while being careful to not lose sight of the relative, individual strengths of each business. Alastair often describes Ground Control as a large company that feels small. All three companies were founder-led. That entrepreneurial spirit, creativity and additional care taken with customers when they are dealing with a smaller firm, is something all teams work hard to maintain, despite the increasing headcount.

As Alastair puts it – “we start by listening… a lot of the time the real problem that needs solving isn’t necessarily the one they brought to us in the first place and we’re very good at figuring out the underlying issue.”

When talking of the anniversary, Alastair states – “It says a lot about a business, that you stay in business for 20 years; the company is obviously good at what it does. But we’re also fresh; we bring the best of both worlds. Money can’t buy twenty years’ experience, but at the same time we’re fully focused on changing ourselves up, all the time, every year, something new, something better. How can we do a better job next year than we did this year? I think that’s what’s great for customers.”

Looking to the future, Alastair credits Horizon Capital with empowering the company to build new things, grow the team, bring in new skills, as well as retaining and protecting existing experience and expertise. Alastair concludes, – “we’ve been able to leverage our history, our existing resources and investment to build new things, and what comes out of that is something which is genuinely great for the market, and great for customers.”

Can We Help?

With 20 years of experience, we can help you make the best choices for your critical communication infrastructure.

We’re not invested in selling you a specific product or connections, just the best solution for your needs.

Complete the form, email hello@groundcontrol.com, or call us on +44 (0) 1452 751940 (UK, serving Europe, Asia, Africa and Oceania) or 800 773 7168 (North and South America).